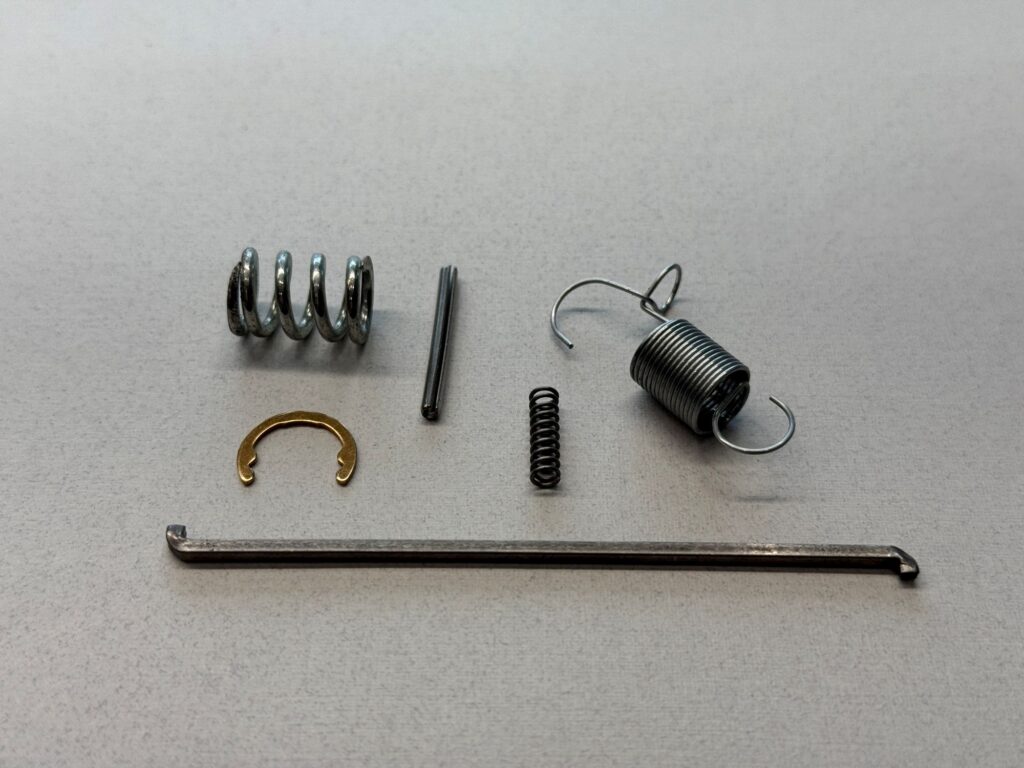

Springs

Torsion, Extension, and Compression Springs

Arcon Ring offers a versatile selection of high-performance springs—including torsion, extension, and compression types—designed to meet a wide range of mechanical needs. Torsion springs provide rotary force and can be customized with unlimited end configurations. Extension springs absorb and store energy while resisting pulling forces, with various end loop styles available. Compression springs, the most common configuration, are crafted to resist axial compression and can be manufactured from multiple materials and shapes. Each spring type is available in a broad range of wire sizes to suit diverse applications.

Torsion Springs

Unlimited end configurations for Torsion Springs are achievable with the use of multidirectional forming slides. (Wire size: Min. = 0.008″ Max. = 0.250″) Torsion springs are helical springs that exert a torque or rotary force. The ends of torsion springs are attached to other components, and when those components rotate around the center of the spring, the spring tries to push them back to their original position.

Extension Springs

Types of ends for extension springs include machine half and full loops, full loops over center or on the side, double twisted, crossover swivel, or extended loops to specifications. (Wire size: Min. = 0.010″ Max. = 0.207″) Extension springs are designed to absorb and store energy as well as create a resistance to a pulling force. It is initial tension that determines how tightly together an extension spring is coiled.

Compression Springs

Manufactured compression springs from round, square or rectangular material, ferrous or nonferrous, furnished with ground or unground ends. (Wire size: Min. = 0.005″ Max. = 0.207″) Compression springs are open-coil helical springs wound or constructed to oppose compression along the axis of wind. Helical Compression Springs are the most common metal spring configuration.